RICOLA KRAUTERZENTRUM

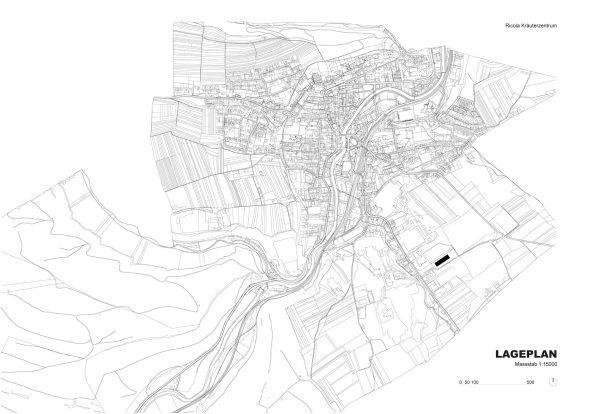

LAUFEN (BASEL), SWITZERLAND

HERZOG & DE MEURON

2014

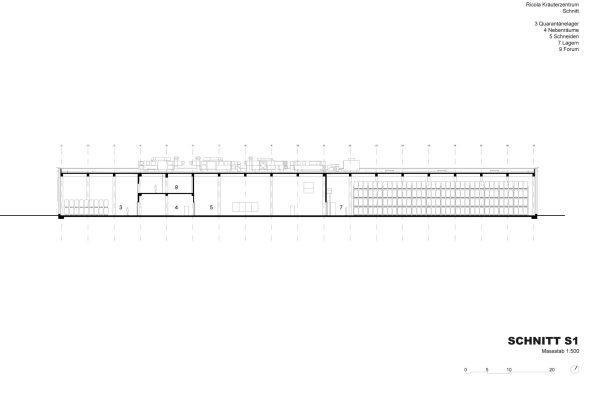

The new Ricola Kräuterzentrum is a central location for processing these herbs from the Swiss mountains. The construction project known for the advanced use of rammed earth was completed by renowned Basel architecture firm Herzog & de Meuron and the company Lehm Ton Erde Baukunst GmbH. The center cleans, dries, cuts, stores and mixes 1,400,000 kilograms of fresh herbs every year at a central location to create the unique Ricola herb blend that is the vital ingredient of all Ricola products.

Following 16 months of construction, the new Ricola Kräuterzentrum, which is directly adjacent to the production facility in Laufen, entered into operation at the beginning of May 2014. The herb center is located in a half-agricultural and industrial landscape. Its elongated shape references the pathways and the hedges which define the area and supports the industrial processing of herbs.

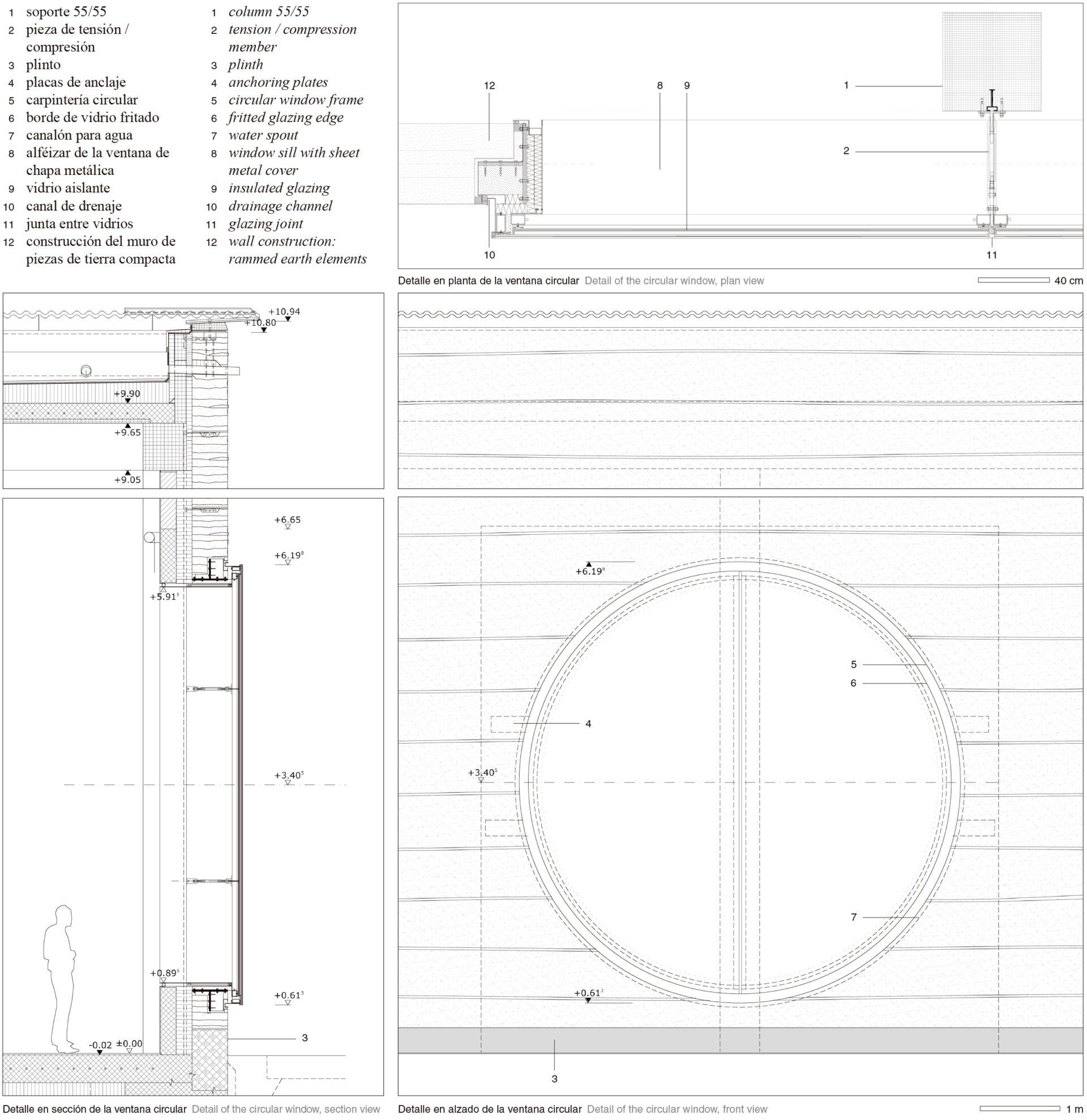

The Kräuterzentrum is one of Ricola’s buildings which represents the firm’s philosophy and commitment to the environment. Being built out of locally sourced earth, the appearance of the center mirrors the surrounding landscape. The delivery entrance and warehouse facades are monolithic loam walls. The prefabricated earth elements are produced in a nearby factory from locally extracted ingredients. Clay and earth are excavated, mixed and compacted on site to produce blocks of walls. To protect walls from damage caused by wind or rain, a trass mortar made out of volcanic tuff with lime is compacted and applied to every 8 layers of earth in the framework. The formed self-supportive facade with large round windows is linked to the interior concrete loadbearing structure.

The use of the earth helps to regulate humidity and has positive effects on the use of energy and climate control. To improve ecological balance, photovoltaic roof modules and waste heat from nearby production center are used.